✕

Artificial Intelligence (AI) is reshaping industries globally, and new innovations are generating benefits across the manufacturing sector. Quality control is one of the biggest opportunities for the application of AI technologies. In a recent webinar titled “AI for Electronics Quality Control: Practical Applications and Case Studies,” I explained how machine learning and AI can revolutionize quality control in electronics manufacturing. I want to highlight the profound impact of these technologies on improving processes, reducing costs and improving product quality.

Key technologies in the AI toolbox

AI is not just a “thing,” it is a set of technologies – a toolbox filled with various tools, each tailored to specific tasks. For the world of electronic manufacturing, the most relevant tools are:

- Machine Learning (ML) and Deep Learning: These technologies allow manufacturers to analyze larger data sets and uncover insights that would otherwise be impossible to derive from statistical analysis alone. Machine learning can be used for tasks such as defect classification, object detection and anomaly detection. Machine learning can work with datasets containing 100 to 1,000 data points, while deep learning requires even larger datasets. In visual inspection tasks, both technologies can significantly improve accuracy compared to conventional computer vision approaches.

- Large Language Models (LLM): This is the technology behind ChatGPT and shows promise in allowing users to interact with their data or documents through a chat interface. However, the technology is relatively new and still generates words via a statistical engine, not from a true understanding of the content.

- Generative AI (Gen AI): Generative AI is a relatively new technology that creates new media from prompts. There have been some attempts to use Gen AI to generate images of defects to then power ML or Deep Learning models, but I’m skeptical whether this would work outside of a proof of concept. We have found in our own research that even human-caused faults can pose problems for training models if the faults are not truly representative of real-world failures. So I’m skeptical about generating faults for training.

- Mathematics: Last but not least, basic statistics form the basis of everything else that AI is built on. Statistics has many applications in quality control and is also an essential tool in the AI toolbox.

Quality control is the best and first application of AI for manufacturing

Manufacturing is complex and there are many areas where AI might be able to improve key KPIs. In my opinion, quality control is the best AI use case to target first – for three reasons:

- Quality often has access to data. Quality data sets are large and well-structured, which creates a learning opportunity for AI. However, even small data sets, such as those collected from just 100 units, may still be enough for AI to provide benefits. Quality teams often have unique access to cross-functional and cross-vendor data sets to feed into AI applications.

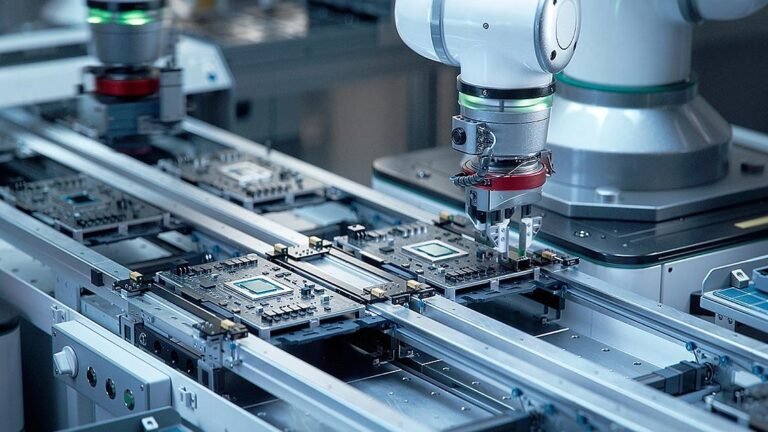

- Automate human visual inspection: AI can effectively handle repetitive inspection tasks, which are often tedious and prone to human error. As I pointed out, “humans are not particularly good at inspection,” but it is an area that AI can excel in because once trained and tuned, it will perform consistently without tiring. Leveraging AI for visual inspection can improve overall product quality while reducing line operational costs.

- Quality is uniquely positioned to measure and quantify impact. Improving quality can significantly affect a company’s bottom line, so the return on investment (ROI) of investing in new technology is easier to demonstrate compared to other places within the organization. Likewise, quality managers can bridge the gap between operations and business metrics. They directly understand the costs associated with poor quality. General quality improvements have a significant impact on the bottom line, even more so than improvements in engineering or operational efficiency.

Practical applications of AI to improve the quality of electronics

One of the most common applications of AI in manufacturing is inspection. AI can significantly reduce inspection preparation times and improve the accuracy of defect detection. Traditional computer vision (CV) systems require extensive configuration and tedious rule programming. When changes are frequent, such as during NPIs or during periods of continuous improvement in the production line, CV systems are impractical because their rules must be updated with each new version of the product. As a result, CV-based computer vision systems are typically only used for “one problem, one camera” applications – where a specific failure mode is so financially burdensome that it justifies the full cost of the camera and its setup. Unfortunately, the CV can only be used to identify known issues. If you haven’t preprogrammed fail mode, the system won’t find it.

AI-based systems, on the other hand, can adapt to design or process changes in real time. AI algorithms can be trained on datasets in just minutes, making AI easier to deploy and scale. Additionally, they can detect known and new issues. For known issues, machine learning algorithms can outperform traditional methods by identifying defects with “superhuman” accuracy. The typical industry benchmark for human visual inspection is around 80% of defects detected – AI can detect up to 99%.

AI can also identify new problems, i.e. those that have not been identified before, by detecting defects that might otherwise slip through the cracks. The conventional approach to discovering new problems is to have an engineer sit at the end of the line, look at the units, and see if there is anything that wasn’t in the initial inspection procedure that needs to be added. But that requires an engineer to be in the right place at the right time – a bit of luck. And luck is not a good strategy.

Another area where AI is creating significant business impact is in dark yield. Dark yield is the defects you should have caught at the factory but missed – it’s dark because you can’t really measure how many units are leaking except in field performance and complaints. A poorly mated connector or assembly with less thermal paste than it should pass end-of-line functional testing but may not hold up in the field. Because AI can perform detection at higher levels than humans and can also detect new problems, it is well suited to revealing dark performance within the factory floor, which is a much better place to find defects than in the field.

Case study: A communications leader adopts AI

A $50 billion communications company that makes radios for first responders was facing quality issues, defects that went undetected until the product was already in the field. The high stakes of this product, used by firefighters and other first responders, have made quality control a top priority.

The company decided to implement AI-based inspection systems to detect defects that human inspectors missed. By running a proof of concept with 1,000 units, they found that AI could detect critical defects, such as switched buttons and missing labels, that had gone unnoticed by human inspectors. The company was able to easily calculate its ROI with the addition of AI inspection. They were able to measure the reduction in inspection time and evasion rate, how many fewer operators they needed and what the break-even point was. In this case, it was a month.

Demonstrate proof of value to drive AI adoption

Despite the obvious benefits, adding AI to an existing operation comes with challenges. One of the biggest hurdles is change management: convincing teams to adopt new technologies and integrate them into their workflows.

People don’t like change. It’s important to think about how to introduce new technology to users so they can see the value and impact on their personal work and KPIs, as well as the company’s KPIs. One way to convince both users and management is to launch a proof of value pilot project. Unlike a proof of concept, which tests the functionality of a technology, a proof of value tests the technology’s ability to move things forward on a critical KPI. By calculating the ROI of AI-driven quality improvements and quantifying the cost of quality leaks, manufacturers can justify the investment and gain buy-in from key stakeholders.

Conclusion: the future of AI in quality control

AI is a powerful tool for improving quality control in manufacturing. With its ability to detect known and unknown defects, automate repetitive tasks, and reduce costs, AI is poised to transform the way manufacturers ensure the quality of their products.

Quality leaders are best placed to lead this transformation. AI is a big improvement over existing conventional methods of quality control. Barriers to adoption can be overcome by establishing proof of value, where you can actually see this technology working.

The future of quality control is one where machines and humans work together to achieve unprecedented levels of precision and efficiency. The question is not whether manufacturers should adopt AI, but how quickly they can start reaping the benefits.